Steam, gas, and hydro generators (up to 700 MW)

AC/DC motors

Power transformers

Coils & synchronised machines

Our processes are rooted in precision, reliability, and promptness. We’ve adopted Kaizen practices, OEM partnerships (Toshiba, ABB, WEG), and IEC-compliant quality checks to ensure consistent performance and reduced downtime for your business.

To be the most trusted partner in extending the life of electrical machines by delivering world-class MRO solutions that improve efficiency and save costs for our customers.

To deliver meticulous inspection, repair, rewinding, and testing services, backed by ISO 9001:2015 standards and a skilled workforce—ensuring customer satisfaction and reliability at every stage.

Steam, gas, and hydro generators (up to 700 MW)

AC/DC motors

Power transformers

Coils & synchronised machines

Our processes are rooted in precision, reliability, and promptness. We’ve adopted Kaizen practices, OEM partnerships (Toshiba, ABB, WEG), and IEC-compliant quality checks to ensure consistent performance and reduced downtime for your business.

To be the most trusted partner in extending the life of electrical machines by delivering world-class MRO solutions that improve efficiency and save costs for our customers.

To deliver meticulous inspection, repair, rewinding, and testing services, backed by ISO 9001:2015 standards and a skilled workforce—ensuring customer satisfaction and reliability at every stage.

Precision is at the heart of RKELC. We restore life to generators, motors, and transformers with meticulous rewinding, repairs, and testing.

Every stage of our work is guided by accuracy—ensuring performance without compromise.

Efficiency drives our solutions at RKELC. From re-engineering and design to raw material selection, repairs, and testing, we focus on improving machine output.

Our approach reduces downtime and enhances long-term reliability.

Reliability defines our promise at RKELC. Each machine undergoes strict IEC-compliant quality checks and final inspections before delivery.

This ensures trouble-free operations, minimal downtime, and consistent performance for our clients.

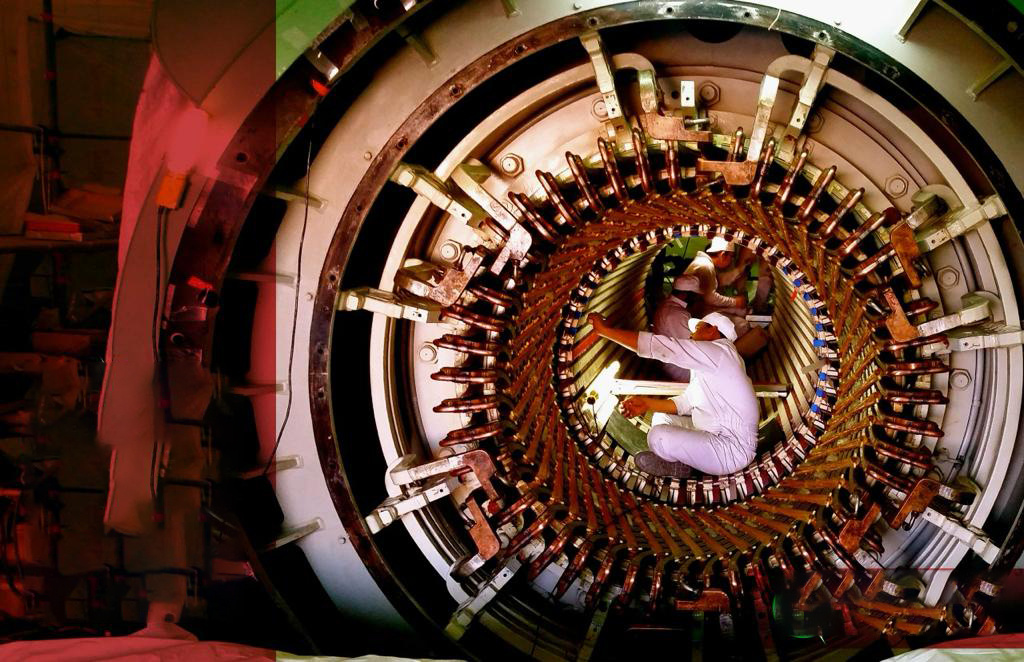

375 MVA GENERATOR STATOR and 375 MVA 15KV 3000RPM TOSHIBA

Make Steam Turbine Generator

Client: M/s. Ministry of Electricity & Water, Kuwait (Toshiba, Japan & A.G.G. Kuwait).

Complete rewinding of DM water-based generator stator with completely new coils with new insulation class -” F”.

———————————————————————————————

188 GENERATOR ROTOR(Below photo belongs to 188 MVA) and 15 KV, 3000 RPM, TOSHIBA

make – Steam Turbine Generator

Client: M/s Ministry of Electricity & Water, Kuwait (Toshiba, Japan & A.G.G. Kuwait).

Complete rewinding with new copper conductor and new insulation and carrying out dynamic balancing.

375 MVA GENERATOR STATOR and 375 MVA 15KV 3000RPM TOSHIBA

Make Steam Turbine Generator

Client: M/s. Ministry of Electricity & Water, Kuwait (Toshiba, Japan & A.G.G. Kuwait).

Complete rewinding of DM water-based generator stator with completely new coils with new insulation class -” F”.

———————————————————————————————

188 GENERATOR ROTOR(Below photo belongs to 188 MVA) and 15 KV, 3000 RPM, TOSHIBA

make – Steam Turbine Generator

Client: M/s Ministry of Electricity & Water, Kuwait (Toshiba, Japan & A.G.G. Kuwait).

Complete rewinding with new copper conductor and new insulation and carrying out dynamic balancing.